This site is available in multiple languages: Deutsch, Русский, عربي.

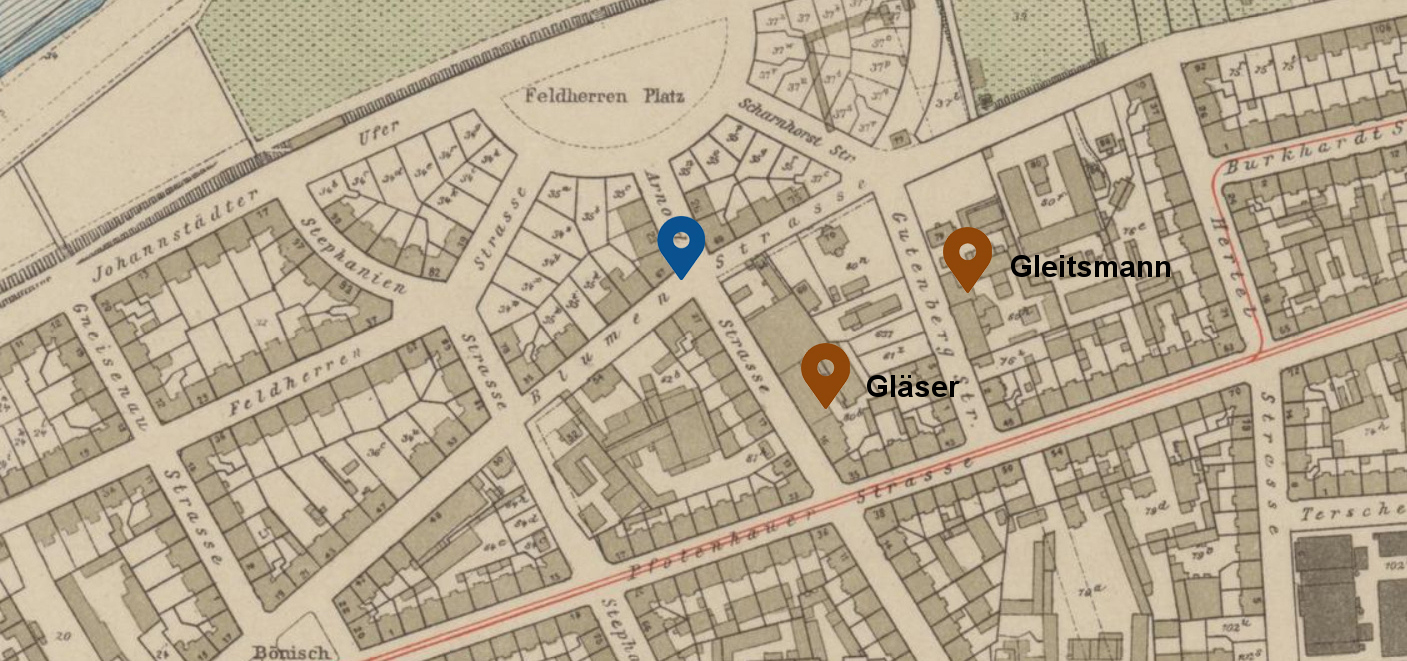

Turn right onto Pfotenhauerstraße, cross the street at the pharmacy and turn onto Arnoldstraße. You will arrive at the fith location on the historical walking tour.

Before 1945: Aid, automobiles and ink

Arnoldstraße

Arnoldstraße runs from Gerokstraße, past Trinitatisfriedhof, on to Thomas-Müntzer-Platz. It was named after Johann Christoph Arnold (1763–1847) in 1893. Arnold worked as a publisher, newspaper owner, arts patron and city politician. In addition, he founded the Arnoldischen Buchhandlung (bookstore). During the Nazi era, the developed section of Arnoldstraße was called Litzmannstraße. Karl Litzmann (1850–1936), an infantry general and MP in the NSDAP-Reichstag, also served as the Weimar Republic’s last doyen d’âge. The street’s name was changed back on July 24, 1945.

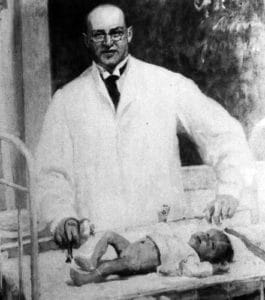

On August 1, 1898, a children’s polyclinic was opened at Arnoldstraße 1. It was the world’s first polyclinic for the in-patient care of infants, and Arthur Schloßmann was the man who ran it. In his clinic, Schloßmann provided “free medicine and remedies in emergency cases, as well.” The clinic’s goal was to lower infant mortality through polyclinical care and improvements in infant nutrition. Clinic personnel set up warming stations to care for premature births: the forerunners of modern-day incubators. Schloßmann’s institution paved the way for today’s pediatric unit of the Universitätsklinikum.

Find more information on the history of Arnoldstraße here.

Gläser Automotive

One of the most emblematic firms on Arnoldstraße was Heinrich Gläser’s Karosseriewerk, founded in 1864. In service to the royal court, the works began by supplying, among others, the royal stables and the royal high Oberstallamt with coaches. In 1900, with the participation of Radeberg blacksmith, Emil Heuer, the factory produced 20 luxury-equipped coaches per year. Serial production of limousines began in 1904. The first royal limousine to leave the workshop came one year later in the form of the Triple-Phaeton-Bauform (open car with three rows of seat), developed by the Karosseriewerk.

Over the years, the company came to specialize in cabriolet bodies and prepared prototypes for various clients, including Mercedes, DKW, Horch and Wanderer. In 1933, as a result of the worldwide financial crisis and sinking sales of luxury coaches, Heuer was forced to declare bankruptcy. In 1935, the newly founded Gläserkarosserie G.m.b.H, under Gläser’s son-in-law, Willy Bochmann, secured a lucrative contract with the Wehrmacht, and completely reoriented its business toward armament manufacturing. For a short time, there was also an SS disciplinary work camp for male prisoners.

Find more information on the history of the Karosseriewerk here.

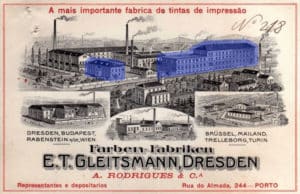

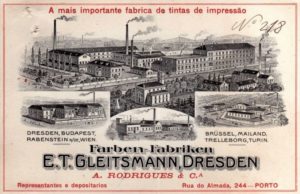

E.T. Gleitsmann-Farben

The chemical factory for dry inks, founded in 1858 by Emil Theodor Gleitsmann, moved to Dresden in 1867, and by 1900, had already expanded down Gutenbergstraße over several lots totaling 8,000 square meters. The firm produced inks for letterpress and lithography, as well as ready-made color products. Beyond Gutenbergstraße, there was also a flax oil varnish producer with oil storage rooms, two soot distilleries and a resin distiller. Alongside high-quality standard printing inks, E. T. Gleitsmann also produced secure printing inks for banknotes and postage stamps. Up until 1920, the firm leveraged its growing success to found subsidiaries in Italy, Sweden and Austria, and is today headquartered in Bavaria.

Find more information on the history of the Farbenfabriken E. T. Gleitsmann here.

After 1945: Wartburg and Training

Gläser becomes a state-owned enterprise (VEB)

The bombs which devastated Dresden on February 13th and 14th 1945 also destroyed the industrial facilities of Gläserkarosserie G.m.b.H. After crudely restoring a few workshops on Arnoldstraße, the 40 or so remaining workers began manufacturing backpacks and handbags, whereas the wheelwrights specialized in handcarts and trolleys. Repairs were also made to motor vehicle structures. For its first large order, the factory produced four “6-window Pullman limousines” for the Russian city commander, as well as 25 urgently needed DKW F8 delivery trucks.

In 1953, the Gläser factories in Radeberg and Dresden joined the VEB Karosseriewerk Dresden (VEB = state-owned enterprise), using the brand, “Industrieverband Fahrzeugbau (IFA)”. Aside from the IFA-F8, they later produced body parts for the limousine-version of P70 and, after 1956, the Wartburg 311.2 Cabriolet. Bodyshell manufacturing was done in Dresden’s manufacturing district on Industriestraße; paintwork and fixing the body to the chassis took place on the newly created Taktstraße, on Arnoldstraße. In 1963, the Karosseriewerk coated Wartburg parts using a two-coat synthetic resin assembly line. In 1967, it began serial production of the Wartburg W 353 Tourist.

In 1991, the Arnoldstraße factory ceased automobile production, and in 1994, the firm was privatized as “Karosseriewerke Dresden GmbH (KWD)”, with its sole base in Radeberg. After tearing down the neighboring structures and converting the remaining office, various companies rented space in the building, including the well-renowned gaming pub “Triangel” until 2018.

Find more information on the history of the Karosseriewerk here.

|

|

E. T. Gleitsmann becomes the SGB

After the worst damage from the war was cleared in 1949, Neues Leben, an industrial trade school for the varnish and paint industry, was built on the site of the Farbenfabrik E. T. Gleitsmann. After multiple restructurings, it became first the head education division of the VEB Kombinat Lacke und Farben in 1983, and finally in 1991, the “Sächsische Bildungsgesellschaft für Umweltschutz und Chemieberufe Dresden mbH (SBG)”.

After the successful privatization of the SBG through the “Verein zur Förderung gemeinnütziger Bildungs- und Beschäftigungsmaßnahmen Dresden e.V.” in 1992, the foundation “Zukunft durch Bildung” (Future through Training) took sole control of this historic Johannstadt training center. Today, the SBG plays a central role in the training and continuing education of those in the fields of science and environmental technology. Over 120 partners in chemical, medical and bio-management manufacturing and research as well as water, wastewater and recycling management send their apprentices to train with the SBG. The SBG is also charged with vocational training for painters and varnishers.

Text: Matthias Erfurth, Matthias Kunert, Henning Seidler

Editorial deadline: January 2024